At a Top Secret location, deep in the heartlands of Scotland, it was the first meeting of the year for the Forth and Clyde Area Group.. To mark a new start to the year and perhaps some resolutions to advance the various projects and railways of the Group, we had twelve in attendence, Alisdair, Alistair, Alastair, Graham, Simon, Jim, James, Nigel, Andy, Chris, Stuart and I, your humble scribe, Martin.

There was no theme to this months gathering, however it was announced our wee layout - Mearns Shed - has been promised, dead or alive, for the Finescale Zone at the

Perth Model Railway Exhibition, less than six short months away and so the Glorious Leader, a Alisdair has started to insist we call him, spent a bit of time instructing us all to remove various appendages from various orifices so that the layout is fit and ready to be viewed by the General Public.

Various elements of how we'll exhibit the layout were discussed - the plan is to have a box which accompanies the layout to have it at a decent viewing/operating height - The Glorious Leader had brought along a crate that apparently belongs to the Group, it was brought along and set up to test the height and stability - here Andy and Alisdair assess the height. The crate also contained a DC controller and some black curtains, both of which may prove useful!

Stuart had brought along one of his baseboards. Stuart has been wrking on the mill building at the front at previous area group meetings and now we can see it in situ. The viaduct at the back is the next challenge for his building technique. For those just joining us, the mill buildings are made from 1mm Acrylic sheet, cut to size and glued to shape, the outer faces are made from 1.5mm mountboard, cut to shape, windows excised and coloured with a mix of acrylic paint and weathering powder.

The mill isn't quite complete, but it's an impressive feature - this board measures 4' x 3' and dominates the foreground here. This is the central board of Stuart's railway, another 4' section will be added at each side, before a loop round to a rear fiddle yard. There will also be rail served sidings in front and to the side of the mill, and a canal in front of the mill with lochs leading off to the left hand side of the image.

Stuart was in the process of sizing up part of the board to include the

Magnorail system so he can have busses running behind the mill. Stuart had brought along two packs of the Magnorail and was showing us how it all goes together.

Stuart is an N Gauge modeller, but plans to operate with Code 40 rail, and intends to keep things as close to finescale as he can without fully converting. I include this comment not to disparage Stuart or his layout - I'm blown away by the detail and complexity of the Mill to the extent that I currently have some sheets of mount board running through the Cricut as I write this update to see if I can replicate Stuart's techniques for my own nascent layout. Rather to show that our Association (because for all the jokes about the benevolent dictatorship of the Glorious Leader, it is *our* association), is a broad church, and that we can both teach and learn to/from our course-scale comrades.

Graham took the admonition of the Glorious Leader to heart and was busy in a 3D drawing program, tinkering with the design for the Shed itself. Graham intends to 3D Print the shed in a series of sections and combine them to create the whole. Some test prints have previously been discussed on this blog - Graham had brought these along to discuss the mortar courses, however the project had stalled at this point, as many do, and he was using the Area Group meeting to go back to the project. I didn't quite catch the conversation here, but I was assured it related to 3D CAD software...

Alastair is one who normally uses the session to work on his various 3D print designs, however today we caught him doing some "Proper modelling", working on a turnout for his intended layout. By the end of the session Alastair had completed this turnout, now having two complete, hand built turnouts.

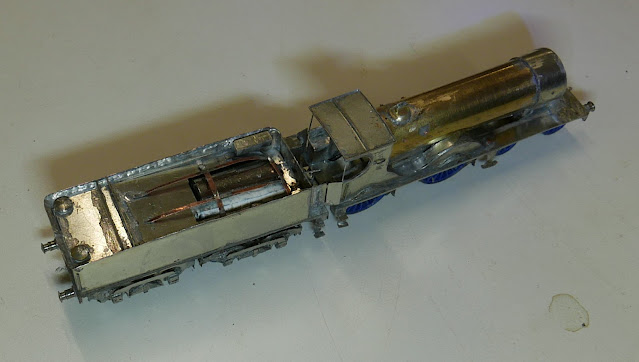

Jim was working on his new project, a Caledonian Railways 900 Class, better known as the Dunalastair III Class, these are express passenger locomotives, this one from Jim's own etches. Readers of RMWeb, might have seen

Jim's progress to date, and his recent issues with the brass tube for the boiler and issues with his stay alive circuit. The boiler issue had been machined by Tim of Copenhagen Fields fame, but Jim had found issues bending the tube to form the firebox sides - Nigel came to the rescue with his Resistance Soldering Unit (more in a moment), and between Nigel and James, progress was made on the stay alive circuitry

The Dunalisdair III in its small scale glory. The level of detail on this wee beastie is something that has to be seen to be truly believed.

James and Jim ponder the intricacies of the stay alive circuitry that Jim will fit into the tender of the locomotive.

As mentioned above, Nigel had brought along his Resistance Soldering Unit, and was assembling buffer stops, and gave a demonstration on how it works. If you excuse the dodgy photography, Nigel had set up some scrap etch and showed how to make it glow red hot. Then how to solder with it...

Nigel's unit is from

London Road Models, and retails at £245. Whilst this is significantly more than either of the soldering irons I've bought (which together come to about £50...) Nigel did demonstrate it's ubiquity and usefulness for those doing a lot of soldering. At about the price of a DCC Sound locomotive, it's food for thought.

Simon was working on some British Railways Mk1 Carriage Battery boxes. Someone who will remain nameless had sold him a Farish RMB at the Scottish Minimeet last year which had apparently come without a battery box. Despite searching high and low, the offending part could not be found and so one of the association etches had been procured as an apology.

Simon had also brought along his Christmas present, a Metro-Cammell Lightweight DMU (latterly BR Class 101). Simon had been busy, adding drivers, passengers and weathering the loco. He described a photograph from Mallaig of a unit sitting in the bay platform that he had used as reference to weather the loco. It was certainly looking the part.

Chris was working on his Midland/LMS Fowler 4F, or specifically detailing the tender. This is the now unavailable Mike Raithby etch and is certainly looking lovely.

Alistair was planning the painted backscene for Mearns Shed. He'd constructed a 5mm =1" model of the model from foamboard to help him visualise the scenery and the required shapes and textures. This will allow Alistair to paint the appropriate shades and features onto the backscene.

On the subject of Mearns Shed, although not photographed, the Glorious Leader (Alisdair), was working on ash pits for the layout. The holes for these were cut around this time last year and have been awaiting filling since then. By the end of the session, at least one was done, proving that Alisdair can do some work at an Area Group meeting...

An ongoing house move has removed Andy from his projects and tools, and as such he spent some time talking to each of us, discussing our projects and techniques on show.

James, who sat opposite me for most of the meeting, making my absence of knowledge as to what he was doing inexcusable, was working on some circuitry as well as assisting Jim with his stay alive problems. James have brought along donuts, which kept us fuelled as we modelled and worked.

Now, unless I've miscounted, that just leaves me (Martin), who remarked to several people "I need to remember to photograph my wee project at the meeting because I don't think I've remembered to since I became Junior Assistant Press Intern". Then promptly forgot to take any photographs...

Back at the last Perth model railway show, I had displayed some 16T mineral wagons behind the Glorious Leader's Black 5 (in Lieu of me having any 2mm locos...), and had been admonished from using a 1/506 Brake Van at the rear of this formation as these wouldn't have run with unfitted wagons. As such, I'd picked up some of the last, now discontinued LMS Brake Van etches from the Association. I'd started a 16T variant at a previous meeting, but had found my 25W iron wasn't cutting the mustard with the brass etched kit.

Now equipped with a 50W iron, I returned to the van, and by the end of the session had completed most of the structure and attached the W Irons. The eagle eyed reader will notice the above photograph also has handrails fitted - this was done after returning home. The roof is still to be soldered on, but 3D printed axle boxes are planned, and as such, the running boards will also need glued on. The plan is to have this finished for Model Rail Scotland so it can be displayed alongside my Mineral Wagons. Maybe by Perth I'll have a loco to put them behind. Notice I didn't mention which year...

Our next Area Group Meeting shall be Saturday 10th February at the Edinburgh Society of Model Engineers premises at Almondale. Further details are within the Association Newsletter. Whether you're one of the people named in this article, a member of the Association who's in the area, or someone curious to see what we do, please get in touch. We've mostly stopped biting...